MPL INTEGRATED PLANT

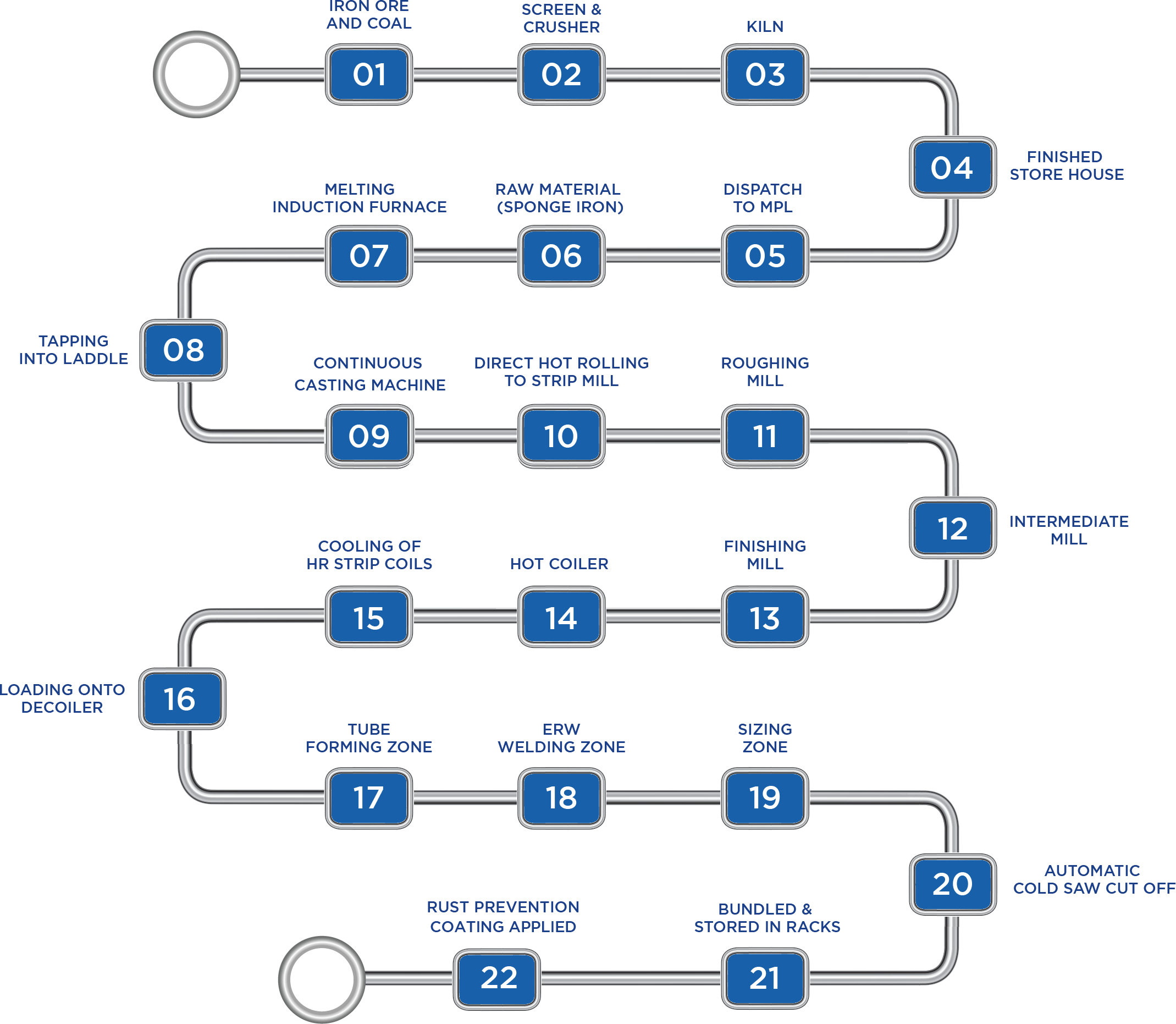

MPL steel pipes are manufactured at a state-of-the-art 150000 sq ft integrated steel facility. The process begins at the DRI plant where iron ore is converted to Sponge Iron (DRI). The DRI is melted in an Induction furnace in the Steel Melt Shop. The hot liquid is moulded and rolled into HR Coils at the Hot Strip Mill. The coils are then converted to MS Pipes in any of the four High Speed Tube Mills.

QUALITY CONTROL

Quality is integral to MPL Steel pipes. We have established stringent quality checks at every stage of the value chain, from sourcing the best quality raw materials till rolling out the finished products. Our world class quality assurance plan ensures that we manufacture products which are at par with global standards.

MPL QUALITY CONTROL PROCESSES INCLUDE

Sourcing the best quality raw material

Using best-in-class manufacturing machinery

State-of-the-art manufacturing processes

Quality control laboratories equipped with testing and analytical instruments, Computerised testing machines.

40+ tests which include physical and chemical tests to check the following attributes

TENSILE STRENGTH

BEND

HYDRO

DRIFT EXPANSION

FLATTERING

MACRO ETR

DIMENSIONAL CHECKS

CORNER RADIUS

STRAIGHTNESS

CONCAVITY/ CONVEXITY

PROCESS

A MANUFACTURING FACILITY THAT’S A CLASS APART

With over 1,50,000 sq ft of covered area, MPL pipes are manufactured in a factory equipped with the best-in-class machines.

STEEL MELTING SHOP

Melting furnace with slab caster where all the magic happens.

HOT STRIP MILL

Exemplary surface finish and versatile mechanical properties

TUBE MILLS

High-speed Mills with Japanese Technology of W Forming and SOLID STATE WELDING TECHNOLOGY From THERMATOOL TM

WORLD CLASS TESTING MACHINES

Lement state-of-the-art spectrometer Computerised universal tensile machine Bend test machine Hydro test machine.